ABOUT US

CROSSBAUM® is the registered trademark of our company Argo Baum. We are an European manufacturer of medical devices, specialized in dentistry, built on a solid experience, that combines in-depth technical and business expertise, with a strong industrial knowledge of medical devices across international markets.

In September 2015, due to our long-term professional experience in the field of dentistry and having been producing for several international brands in the dental area, we decided to launch our own brand of Prosthetic Components for Oral Rehabilitation – CROSSBAUM® – providing new prosthetic solutions for implantologists and dental technicians, adding value to the market.

We use the State-of-Art technology in the field of dentistry and the most challenging materials, assuring extreme precision and quality in our products, putting our upmost care in every product that we make.

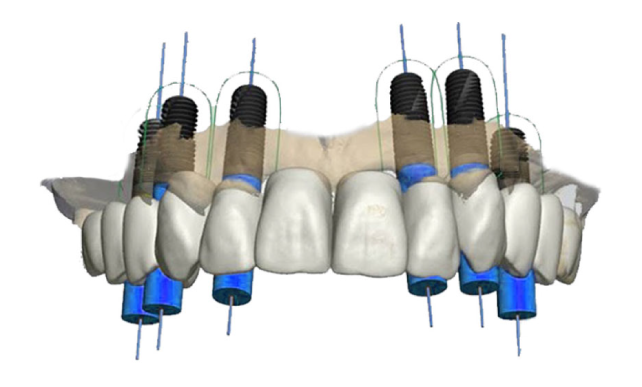

CROSSBAUM’S PROSTHETIC COMPONENTS FOR ORAL REHABILITATION ARE

COMPATIBLE WITH THE DENTAL IMPLANT SYSTEMS MOST USED WORLDWIDE

In CROSSBAUM® we guarantee the best product at the best price on the market, which makes us the ideal partner to add value to your business model.

In CROSSBAUM® we work hard every day to achieve total satisfaction of our customers, by offering dental clinics and laboratories significant cost savings, ensuring that production deadlines are met and the delivery is made in time, always maintaining high quality standards and offering an exemplary aftermarket support.

CROSSBAUM® OFFERS AN INTEGRATED DIGITAL SOLUTION

FOR DENTISTS AND DENTAL LABS.

CONTACT A SPECIALIST

Get immediate advice on products tailored to your needs.