GENERAL FEATURES

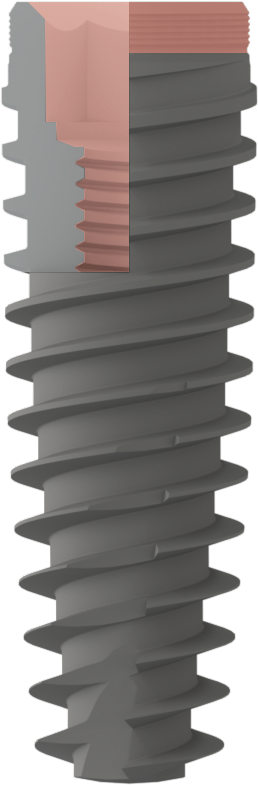

Connection

Screw-Vent® compatible internal hexagon can generate a virtual cold weld which, thanks to the very small dimensional tolerance of the connections, allows a better preservation of bone levels.

Surface Treatment

Obtained through chemical etching, decontamination, and cold Argon plasma treatment, makes the surface hydrophilic and increases its wettability. Postoperative clot stability improves osseointegration processes.

Cutting

Self-tapping

Active Apex

With aggressive thread ideal for post-extraction sites

Platform

Ø 3.75 mm common for all implant diameters.

PTI Microtreated anodised neck

(Pink Tissue Integration) for stable tissue healing.

Material

Commercially pure medical Grade 4 Titanium (ASTM F67). Cold worked: strength +40%.

Cutting Thread

Able to generate ideal conditions of primary stability in any type of bone facilitating the insertion and reducing stress in the most mineralised bone components. Double start thread with 1.8 mm pitch for minimal trauma and faster insertion.

TECHNOLOGY

Colico is a small town located at the northern arm of Lake Como: lapped by the waters of Lario, which with their continuous movement inspire dynamism and resourcefulness, and protected by the solid rocks of Mount Legnone, a natural example of solidity and perfection. In 1983 it inspired two young technicians, Olivio Della Bella and Romolo Micheletti, to design and manufacture dental implants: employed by a dental practice to create one of the first two-stage lines in Italy.

It is a period of innovation and experimentation in a market led by a limited number of visionaries, who, inspired by the studies on the titanium osteointegrability carried out by Prof. Per-Ingvar Branemark, courageously propose a revolutionary idea: to insert titanium screws into the bone to artificially replicate the root of a missing tooth.

Since then, more than thirty years have passed – all spent in the design, development and production of implants, prosthetic components and surgical instruments – during which the fundamental values have always remained constant: respect for people, passion and enjoyment at work, attention to customer’s needs, desire of innovation.

Based on these pillars, Biomec today is a solid and modern company. Thanks to the daily activity of more than fifty employees and to the technology concentrated in twenty last-generation CNC machines of the production department, 100% of its devices are manufactured internally. Therefore, the reputation of Biomec in the world is definitely “made in Italy”.

DIAMETERS AND LENGTHS

Ø 3.30 mm

Length:

8.5 mm | 10.0 mm | 11.5 mm

13.0 mm | 15.0 mm

Ø 3.75 mm

Length:

8.5 mm | 10.0 mm | 11.5 mm

13.0 mm | 15.0 mm | 17.0 mm

Ø 4.25 mm

Length:

7.0mm | 8.5 mm | 10.0 mm | 11.5 mm

13.0 mm | 15.0 mm

Ø 5.00 mm

Length:

7.0mm | 8.5 mm | 10.0 mm | 11.5 mm

13.0 mm

Ø 4.25 mm

Ø 4.25 mm

Length:

15.0 mm | 18.0 mm | 20.0 mm

PTERYGOID

The pterygoid implant of Ø 4.25 mm is designed to treat the severe atrophy of the upper jaw. The implant neck has a surface microtreatment and a 3 mm high anodisation that allows tissue level placement.

DOWNLOAD CATALOGUE

Fill in the form and access all the technical information about Win Implant system.

WIN CAD IMPLANT LIBRARIES

Win Implant Libraries are available for the CAD softwares: Exocad and 3Shape. The digital impression is acquired with Scan Body in a single version for intraoral and benchtop scanners. Download libraries to work on T-Base and Win-Z MUA.

Contact us for direct connect libraries for milled metal.

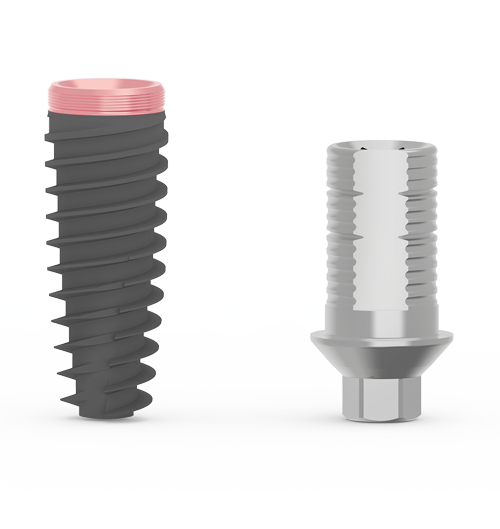

PACKAGE

The WIN-Z implant is supplied with cover screw, grade 5 titanium base with 1mm transmucosal height and abutment screw.

- This component can be used as:

antirotational Titanium base ready to be milled at the desired height with dedicated libraries - definitive straight abutment for healthy mucosal tunnel

- temporary abutment useful for highly aesthetic areas and for an optimal tissue conditioning

- customised healing abutment to guarantee excellent tissue healing

- closed tray impression coping transfer to be used in combination with snap plastic cap

All the implants are contained in a plastic material tube sealed with a screw cap with safety ring, tested to guarantee a 5-year sterility. The sterilisation is performed with BETA rays irradiation validated process, guaranteed and subjected to periodic controls.

- MOUNT FREE – OXY CLAMP SYSTEM:

implant and cover screw are placed in a plastic support with a titanium core - it allows to see implant and cover screw before opening the sterile tube and prevents implant movements for an easier extraction

CONTACT A SPECIALIST

Get immediate advice on products tailored to your needs.